Oerlikon CITOFLUX R71

Rutil-Fülldrahtelektroden

un- und niedriglegierte Stähle

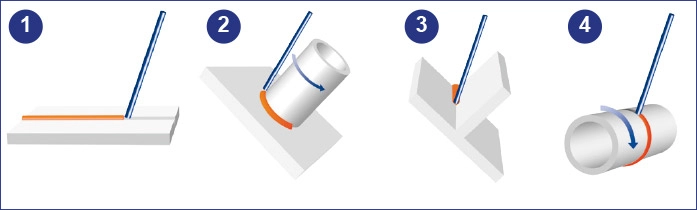

Schweissposition - Stromart - Polung

PA = Waagerechtes Schweissen von Stumpf- und Kehlnäthen (Wannenpostion bzw. Wannelage)

- Strumpfnaht - Blech Wannenposition (1G*)

- Kehlnaht - Rohr rotierend Achse geneigt Wannenposition (1FR*)

- Kehlnaht - Blech Wannenposition (1F*)

- Strumpfnaht - Rohr rotierend Achse waagerecht Wannenposition (1G*)

* US-amerikanische Bezeichnung nach AWS A3.0, ASME Section IX

PB = Horizontales Schweissen von Kehlnaht schweissen (Horizontal-Vertikalposition)

- Strumpfnaht - Blech Horizontalposition(2F*)

- Strumpfnaht - Rohr rotierend Achse waagerecht Horizontalposition(2FR*)

- Strumpfnaht - Rohr fest Achse senkrecht Horizontalposition(2F*)

* US-amerikanische Bezeichnung nach AWS A3.0, ASME Section IX

PC = Querposition bzw. Quernaht (waagrechtes Schweißen an senkrechter Wand)

- Strumpfnaht - Blech Querposition

- Kehlnaht - Blech Querposition (2G*)

- Strumpfnaht - Rohr fest Achse senkrecht Querposition (2G*)

* US-amerikanische Bezeichnung nach AWS A3.0, ASME Section IX

PD = Horizontale Überkopf-Position

- Kehlnaht - Blech Horizontal Überkopfposition(4F*)

- Kehlnaht - Rohr fest Achse senkrecht Horizontal Überkopfposition(4F*)

* US-amerikanische Bezeichnung nach AWS A3.0, ASME Section IX

PE = Überkopfschweissen bzw. Überkopf-Position

- Strumpfnaht - Blech Überkopfposition (4G*)

- Kehlnaht - Blech Überkopfposition

* US-amerikanische Bezeichnung nach AWS A3.0, ASME Section IX

PF = Steigposition bzw. Steignaht schweissen (senkrechtes Schweissen von unten nach oben)

- Strumpfnaht - Blech Steigposition(3G steigend*)

- Kehlnaht - Blech Steigposition(3G steigend*)

* US-amerikanische Bezeichnung nach AWS A3.0, ASME Section IX

PG = Fallposition bzw. Fallnaht schweissen (senkrechtes Schweissen von oben nach unten)

- Strumpfnaht - Blech Fallposition(3G fallend*)

- Kehlnaht - Blech Fallposition(3G fallend*)

* US-amerikanische Bezeichnung nach AWS A3.0, ASME Section IX

- PA

- PB

- PC

- PD

- PE

- PF

- PG

- DC +

CITOFLUX R71 is quality rutile flux-cored wire for gas-shielded metal arc welding of unalloyed steels in all welding positions. Thanks to an innovative flux formulation, the weld pool is easily controllable with outstanding welding properties and optimized gettability. The enhanced filling results in increased current carrying capacity and augmented deposition rate. Higher welding speed allows savings in time and costs. Characterized by very low spatter presence and easy slag removal the bead is smooth and finely rippled without undercut. Low fume emission rate, deep penetration and outstanding weldability make this wire an ideal solution for shipbuilding applications. It can be used in manual and fully-mechanized processes, very well suited for use on ceramic backing and with long liner. It can be used under CO2.

- Normbezeichnung (EN ISO)17632-A: T 42 2 P C 1 H10

- AWSA5.20: E71T1-1/9C H8

- Einteilungun- und niedriglegierte Stähle

- AnalyseC - Mn - Si - P - S

| Produkt | Durchmesser | Länge | VPE | Rollenform (DIN EN ISO 544) | Menge | Preis Pro Spule |

|---|---|---|---|---|---|---|

OERLIKON CITOFLUX R71Artikel-Nr W000386374 | 1.2 mm | 16 Kg | B300 B300 Korb-Ringspule (B)

| Pro Spule CHF 246.10 Ab 10 Spule CHF 196.88 Ab 30 Spule CHF 147.66 Ab 63 Spule CHF 98.44 |

Beschreibung

OERLIKON CITOFLUX R71 - Fülldrahtelektroden für un- und niedriglegierte Stähle -

CITOFLUX R71 is quality rutile flux-cored wire for gas-shielded metal arc welding of unalloyed steels in all welding positions. Thanks to an innovative flux formulation, the weld pool is easily controllable with outstanding welding properties and optimized gettability. The enhanced filling results in increased current carrying capacity and augmented deposition rate. Higher welding speed allows savings in time and costs. Characterized by very low spatter presence and easy slag removal the bead is smooth and finely rippled without undercut. Low fume emission rate, deep penetration and outstanding weldability make this wire an ideal solution for shipbuilding applications. It can be used in manual and fully-mechanized processes, very well suited for use on ceramic backing and with long liner. It can be used under CO2.

Technische Daten

General

Schutzgase

Normbezeichnungen

Zulassungen

Chemische Zusammensetzung (typische Werte in %)

Mechanische Eigenschaften des reinen Schweissgutes

Vorteile

- Gute Zündeigenschaften

- Optimierte Schweisseigenschaften

- Lichtbogenstabilität

Werkstoffe

- S(P)235 - S(P)460

- GP240-GP280

- Shipbuilding steels A.B.D.E.AH32 - EH36